RICOR Development of the Next Generation Highly Reliable Rotary Cryocooler (2016)

Back to Innovation

Itai Regev, Ilan Nachman, Dorit Livni, Sergey Riabzev, Avishai Filis, Victor Segal

RICOR Cryogenic and Vacuum Systems, En-Harod Ihud, Israel 18960

ABSTRACT

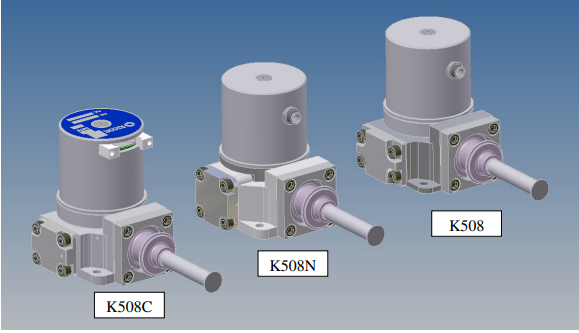

Early rotary cryocoolers were designed for the lifetime of a few thousands operating hours. Ricor K506 model’s life expectancy was only 5,000 hours, then the next generation K508 model was designed to achieve 10,000 operating hours in basic conditions, while the modern K508N was designed for 20,000 operating hours.

Nowadays, the new challenges in the field of rotary cryocoolers require development of a new generation cooler that could compete with the linear cryocooler reliability, achieving the lifetime goal of 30,000 operating hours, and even more. Such new advanced cryocooler can be used for upgrade existing systems, or to serve the new generation of high temperature detectors that are currently under development, enabling the cryocooler to work more efficiently in the field.

The improvement of the rotary cryocooler reliability is based on a deep analysis and understating of the root failure causes, finding solutions to reduce bearings wear, using modern materials and lubricants. All of those were taken into consideration during the development of the new generation rotary coolers. As a part of reliability challenges, new digital controller was also developed, which allows new options, such as discrete control of the operating frequency, and can extend the cooler operating hours due to new controlling technique. In addition, the digital controller will be able to collect data during cryocooler operation, aiming end of life prediction.

Keywords: cryogenic cooler, rotary cryocooler, high reliability, long life, digital controller, bearings, RICOR, K508C.